When it comes to keeping your motorbike or vehicle engine running smoothly, few parts are as crucial as the piston and rings. This guide covers everything you need to know about the piston and rings Westinghouse 4500 224cc diameter 70mm – a popular choice for many small engines, including generators and some motorbikes.

What Is a Piston and Why Does It Matter?

Think of the piston as the heart of your engine. It’s a cylindrical piece that moves up and down inside the engine’s cylinder, helping to convert fuel into motion. The piston:

- Compresses the fuel-air mixture

- Creates power when the mixture ignites and pushes the piston down

- Connects to the crankshaft via a connecting rod, turning linear motion into rotational power

In the Westinghouse 4500 engine, the piston has a 70mm diameter, designed to fit the 224cc engine size perfectly for optimal performance.

Understanding Piston Rings

Surrounding the piston are three types of rings: compression rings, wiper (scraper) rings, and oil rings. These rings perform three critical functions:

- Seal the combustion chamber to maintain pressure during the power stroke

- Transfer heat from the piston to the cylinder walls

- Control oil consumption by scraping excess oil off the cylinder walls

For the Westinghouse 4500, the piston rings are precisely crafted to fit the 70mm diameter piston, ensuring a tight seal and smooth engine operation.

Materials and Construction

The Westinghouse 4500 piston and rings are made from high-quality materials engineered to withstand extreme conditions:

- Piston Material: Typically aluminum alloy, which offers:

- Lightweight properties for better engine efficiency

- Excellent heat conductivity to prevent overheating

- Good durability for small engines and motorbikes

- Piston Rings Material: Usually cast iron or steel

- Cast iron rings conform well to cylinder walls

- Steel rings handle higher temperatures and pressures

- Special coatings like gas nitriding or molybdenum may be applied to reduce wear and improve sealing

Quality Factors

Westinghouse components are known for reliability and durability. Their piston and rings feature:

- Precise manufacturing tolerances for perfect fit

- High resistance to wear and heat

- Specific compatibility with the 4500 224cc engine to prevent issues like piston seizure or compression loss

Quality parts help your motorbike or generator run longer and more efficiently, reducing repair costs and downtime.

Price Considerations

While prices vary by vendor, the Westinghouse 4500 224cc 70mm piston and rings set is generally affordable compared to its durability and performance benefits. Investing in quality parts prevents costly engine damage later. Remember that cheap, low-quality alternatives might save money initially but often lead to expensive repairs.

Compatibility Guide

This piston and ring set is specifically designed for the Westinghouse 4500 series with a 224cc engine displacement. Compatible models include:

- iGen4500

- iGen4500c

- iGen4500DF

- iGen4500cv

If you have a motorbike or vehicle with similar engine specifications, this set might be compatible, but always verify with your engine manual or consult a professional first.

Safety Importance

Using the correct piston and rings is critical for safe engine operation. Improper parts can cause:

- Engine overheating

- Compression loss leading to poor performance

- Excessive oil consumption and smoke

- Risk of engine seizure causing sudden breakdowns or accidents

The Westinghouse 4500 piston and rings ensure your engine runs safely and reliably when properly installed.

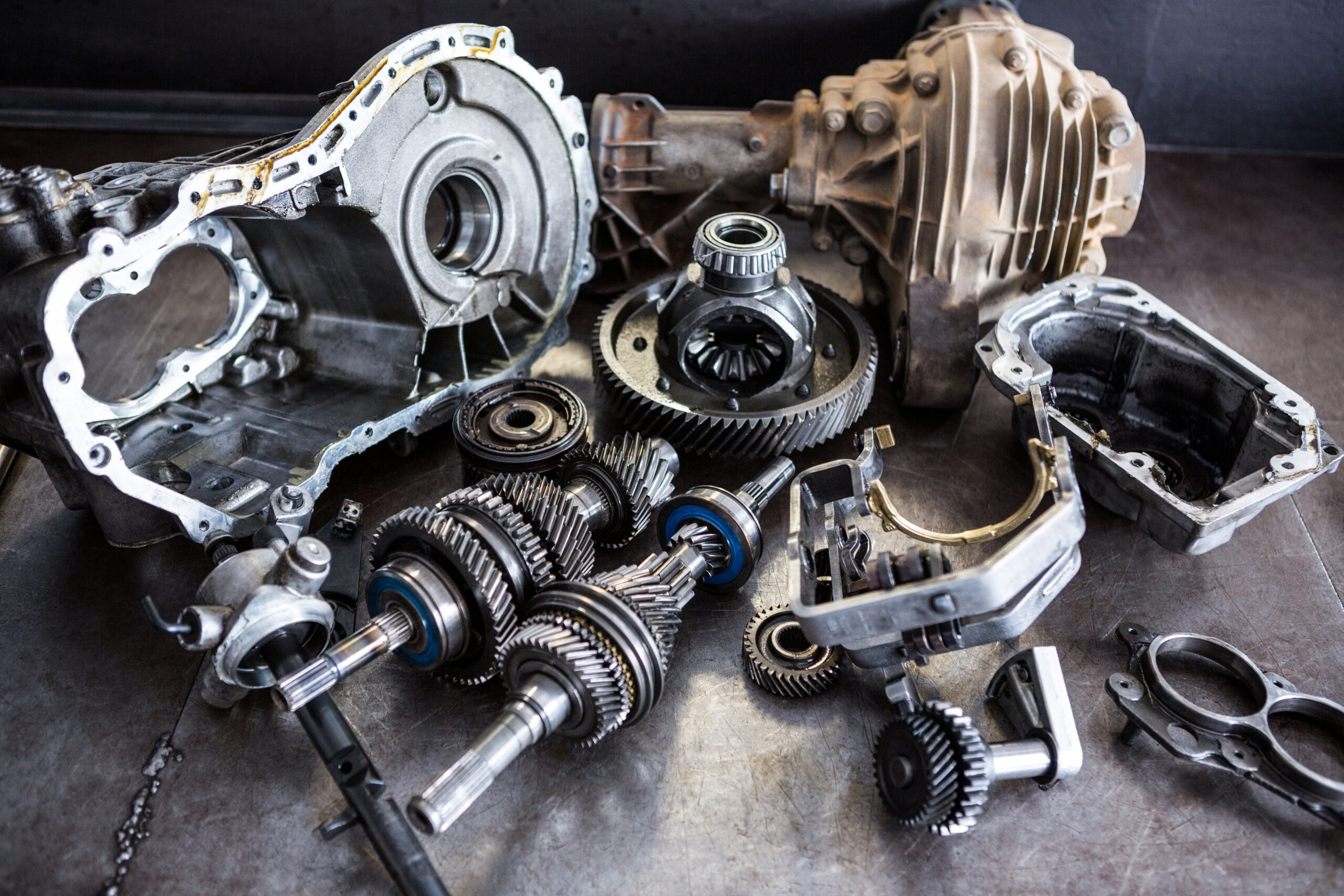

Set Components

A typical piston and rings set includes:

- Piston: The main cylindrical component

- Compression Rings: Usually two, sealing the combustion chamber

- Oil Ring: Controls oil on cylinder walls

- Piston Pin: Connects the piston to the connecting rod

- Clips: Secure the piston pin in place

Each component works together to maintain engine efficiency.

Installation Guide

Proper installation requires:

- Thorough cleaning of piston and cylinder

- Inspection of piston ring grooves for wear

- Examination of cylinder walls for damage

- Careful ring installation without overstretching

- Staggered placement of ring gaps to prevent compression loss

- Proper lubrication before assembly

- Use of a ring compressor tool for smooth insertion

- Secure attachment of piston pin and clips

Following these steps ensures optimal sealing and heat transfer for engine health.

Impact on Performance

Whether for motorbikes or small vehicles, piston and rings affect:

- Engine power and efficiency

- Fuel consumption

- Emissions and environmental impact

- Overall engine lifespan

The Westinghouse 4500 224cc 70mm piston and rings provide smoother operation, better power, and extended engine life when properly installed and maintained.

Piston Rings: Critical for Motorcycle Performance

Motorcycle engines rely heavily on the integrity of their piston rings. These three specialized rings (compression rings, wiper rings, and oil rings) perform essential functions that directly impact your riding experience:

- Seal the combustion chamber to maintain compression, which determines your motorcycle’s power output

- Transfer heat from the piston to the cylinder walls, preventing engine overheating during high-speed riding

- Control oil consumption by scraping excess oil off cylinder walls, preventing fouled spark plugs and blue exhaust smoke

The 70mm piston rings used in the Westinghouse 4500 share dimensions with many single-cylinder motorcycles and small ATVs, making them relevant for powersports applications beyond generators.

Quality Considerations for Motorcycle Applications

The quality of pistons and rings directly affects your motorcycle’s performance and reliability. Premium components offer:

- Precise manufacturing tolerances for optimal compression and power

- Superior heat resistance for high-RPM riding scenarios

- Specific compatibility with your motorcycle’s exact engine specifications

While the Westinghouse 4500 components were designed for generator use, their 70mm diameter specification is shared with many small-displacement motorcycles. When sourcing parts for your bike, focus on manufacturer-recommended components to ensure proper fitment and performance.

Frequently Asked Questions

General Piston and Ring Questions

Q: How do I know if my motorcycle needs new piston rings?

A: Common symptoms include blue smoke from the exhaust, poor compression (weak power), excessive oil consumption, and a “blow-by” sound during acceleration. A compression test can confirm ring issues.

Q: Will a 70mm piston from a Westinghouse 4500 fit my motorcycle?

A: It will only fit if your motorcycle has exactly 70mm bore cylinders. Even a fraction of a millimeter difference makes it incompatible. Always match manufacturer specifications exactly.

Q: How often should piston rings be replaced in a motorcycle?

A: It varies greatly by motorcycle type and usage. Sport bikes ridden hard might need ring replacement at 20,000-30,000 miles, while commuter bikes might go 40,000+ miles. Watch for symptoms rather than following strict mileage guidelines.

Q: Can I replace just the rings without replacing the piston?

A: This is possible if the piston is in good condition (no scoring, cracks, or excessive wear). However, during a rebuild, it’s often economical to replace both since labor is the major expense.

Q: What’s the typical cost of a piston ring replacement for a motorcycle?

A: For a single-cylinder 250cc motorcycle (similar to the 224cc Westinghouse engine size), parts typically cost $50-$150 for quality components. Labor at a motorcycle shop generally adds $200-$500 depending on your location and motorcycle complexity.

Q: How long does a piston ring replacement take?

A: For an experienced mechanic working on a simple single-cylinder motorcycle, 3-5 hours is typical. For a home mechanic doing it for the first time, plan for a full weekend project to ensure proper assembly and testing.

Performance and Modification

Q: Will upgrading to performance rings increase my motorcycle’s horsepower?

A: High-performance rings can help restore lost power and potentially add slight gains by improving compression. However, rings alone won’t dramatically increase power without other engine modifications.

Q: Can I increase my motorcycle’s compression ratio by changing pistons?

A: Yes, installing pistons with a higher dome or different design can increase compression ratio. This can improve performance but may require higher octane fuel and properly matched components.

Q: How do forged pistons differ from cast pistons for motorcycles?

A: Forged pistons are stronger and can handle higher temperatures and pressures, making them ideal for high-performance applications. Cast pistons are more affordable and suitable for stock or mild modifications.

Q: Are there specific piston designs for different types of motorcycles?

A: Yes. Sport bikes often use lighter pistons with reinforced areas for high RPM. Dirt bikes use pistons designed for high impact resistance. Cruisers typically use pistons optimized for torque and longevity rather than maximum power.

Q: How much horsepower can I gain from a full engine rebuild with new pistons and rings?

A: A rebuilt engine with stock pistons and rings should restore original factory power. With performance pistons and proper tuning, gains of 5-15% are possible, depending on other supporting modifications.

Q: Will higher compression pistons affect my motorcycle’s reliability?

A: Higher compression generally increases heat and stress on engine components. With proper fuel octane and engine management, moderate increases can be reliable, but extreme compression ratios may reduce engine life.

Installation and Maintenance

Q: How tight should piston rings be on a motorcycle engine?

A: Piston rings should never be tight against the cylinder wall. The proper specification is measured as “ring end gap” when the ring is inserted into the cylinder. Typically 0.3mm-0.5mm for top rings, but always follow your specific motorcycle’s service manual.

Q: Is it normal for my motorcycle to use some oil between changes?

A: Some oil consumption is normal, especially in high-performance or air-cooled motorcycle engines. However, consumption exceeding 1 quart per 1,000 miles typically indicates ring wear.

Q: Can worn rings damage other parts of my motorcycle engine?

A: Yes, worn rings can allow combustion gases to contaminate your oil (reducing lubrication quality), and oil to enter the combustion chamber (fouling spark plugs). This can lead to accelerated wear throughout the engine.

Q: Can I hone my cylinder without removing it from my motorcycle?

A: This is generally not recommended. Proper cylinder honing requires the cylinder to be removed, thoroughly cleaned, precisely measured, and honed with the correct equipment to ensure proper cross-hatching.

Q: What tools do I need to replace piston rings on my motorcycle?

A: Essential tools include: torque wrench, ring compressor tool, feeler gauges, micrometer, cylinder bore gauge, ring groove cleaner, plastic scraper (for carbon), and a comprehensive socket/wrench set. Model-specific tools may also be required.

Q: Should I replace gaskets when doing a ring job on my motorcycle?

A: Always replace all gaskets that are disturbed during disassembly. At minimum, this includes head gasket, base gasket, and all associated seals. Using old gaskets risks oil leaks and compression loss.

Q: How important is the break-in procedure after installing new rings?

A: Extremely important. Proper break-in seats the rings to the cylinder walls. Generally, this involves varied RPM operation, avoiding sustained high speeds, and more frequent oil changes for the first 500 miles. Follow your specific ring manufacturer’s break-in instructions.

Technical Specifications

Q: What’s the difference between chrome and moly faced rings for motorcycles?

A: Chrome-faced rings offer excellent wear resistance and are ideal for street use. Moly (molybdenum) rings conform better to cylinder walls and are often preferred for high-performance applications. Some premium motorcycle rings combine both technologies.

Q: How much piston-to-wall clearance is correct for motorcycle engines?

A: This varies by specific motorcycle and intended use. Street bikes typically run 0.04mm-0.05mm clearance, while race engines might run slightly more. Always follow manufacturer specifications from your service manual.

Q: Do two-stroke motorcycle engines use different rings than four-stroke engines?

A: Yes. Two-stroke pistons typically use thinner rings, often just one or two compared to three on four-strokes. They may also have different expansion properties to handle the unique two-stroke operating environment.

Q: What causes piston ring flutter in high-RPM motorcycle engines?

A: Ring flutter occurs when rings lose contact with the groove at high RPM, reducing sealing efficiency. It’s often addressed with lighter rings, proper tension, and sometimes gas ports in high-performance applications.

Q: How do titanium and steel connecting rods affect piston performance?

A: Lightweight titanium rods reduce reciprocating mass, allowing faster acceleration and higher RPM limits. This can change the dynamic loads on pistons and rings, often requiring specialized components designed for these higher-stress applications.

Q: Are ceramic coated pistons worth the extra cost for motorcycles?

A: Ceramic thermal barrier coatings can reduce heat transfer, allowing higher compression ratios and improved efficiency. They’re beneficial for high-performance applications but offer minimal advantage for stock or mildly modified street bikes.

Q: How does altitude affect piston and ring performance on motorcycles?

A: Higher altitudes have less air density, reducing compression and power. Performance motorcycles may benefit from different compression ratios when primarily used at high elevations. Ring seal becomes even more critical in these conditions.

Specific Motorcycle Applications

Q: How do dirt bike pistons differ from street bike pistons?

A: Dirt bike pistons often have thicker crowns to withstand impacts from jumps and rough terrain. They may sacrifice some performance for durability and often have different ring configurations optimized for dusty conditions.

Q: Are older vintage motorcycle pistons interchangeable with modern ones?

A: Generally no. Vintage motorcycles often used different materials, designs, and tolerances. While the diameter may match (e.g., 70mm), differences in pin location, compression height, and ring design usually make them incompatible.

Q: Do larger displacement cruiser motorcycles use the same ring technology as smaller bikes?

A: The basic principles are the same, but larger cruiser pistons often employ more robust ring designs to handle increased heat and pressure. Ring thickness and material composition may differ significantly from smaller engines.

Q: How do high-RPM sport bike pistons compare to those in the Westinghouse 4500?

A: Sport bike pistons are designed for sustained high RPM operation (often 14,000+ RPM), requiring lighter materials, specialized skirt designs, and premium ring packages. The Westinghouse 4500’s 70mm piston is designed for lower RPM, longer-duration operation.

Q: Can I use automotive pistons in motorcycle engines if the diameter matches?

A: Almost never. Even with matching diameter (like 70mm), motorcycle pistons have specific designs for higher RPM operation, different cooling characteristics, and unique pin locations. Automotive pistons would likely cause rapid engine failure in a motorcycle application.

Troubleshooting

Q: My motorcycle started making a ticking noise after installing new pistons. What could be wrong?

A: Common causes include: incorrect piston-to-wall clearance, wrist pin not properly secured, ring end gaps aligned, or insufficient clearance between the piston and valves. Immediate investigation is needed to prevent engine damage.

Q: Why is my motorcycle smoking blue after a rebuild with new rings?

A: Blue smoke indicates oil burning and could result from: rings installed upside-down, insufficient break-in procedure, cylinder glaze not properly removed during honing, or oil ring assembly issues. Proper diagnosis is essential before continuing operation.

Q: How can I tell if my piston is damaged without disassembling the engine?

A: A compression test, leak-down test, and oil analysis can provide strong indicators. Significant compression differences between cylinders, metallic debris in oil, and unusual sounds (particularly when cold) often indicate piston damage.

Q: What should I do if my new piston rings don’t seem to seal properly?

A: Verify proper ring end gap specifications, check ring orientation (top/second/oil rings in correct positions), ensure rings are properly seated in grooves, and confirm the cylinder bore has proper cross-hatching. A professional cylinder hone may be necessary.

Summary

The piston and rings for the Westinghouse 4500 224cc with 70mm diameter are precision-engineered components that ensure reliable, efficient engine performance. Investing in quality parts means fewer breakdowns, better performance, and improved engine longevity.